In recent years, the landscape of additive manufacturing has been profoundly transformed by advancements in 3D resin printers, which have become synonymous with exceptional precision and quality. Industry reports indicate that the 3D printing market is projected to grow from $13.78 billion in 2020 to an estimated $62.79 billion by 2028, reflecting a compound annual growth rate (CAGR) of 18.0%. Among various printing technologies, resin printing is particularly celebrated for its ability to produce intricate details and smooth surfaces, making it the preferred choice for professionals across industries such as jewelry design, dental solutions, and engineering prototypes.

Moreover, the demand for high-resolution prototypes has prompted an evolution in 3D resin printer technology, leading to innovations such as LCD and DLP printing methods, which can achieve resolutions up to 50 microns. According to a recent survey by Wohlers Associates, 3D printing is not only boosting design freedom but is also enhancing production efficiency, with over 50% of companies reporting that 3D printing has allowed them to create designs that were previously impossible using conventional manufacturing methods. As we delve into the best 3D resin printers available today, it is essential to understand how these advancements can elevate your projects to new heights of precision and quality.

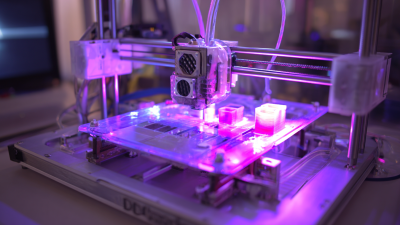

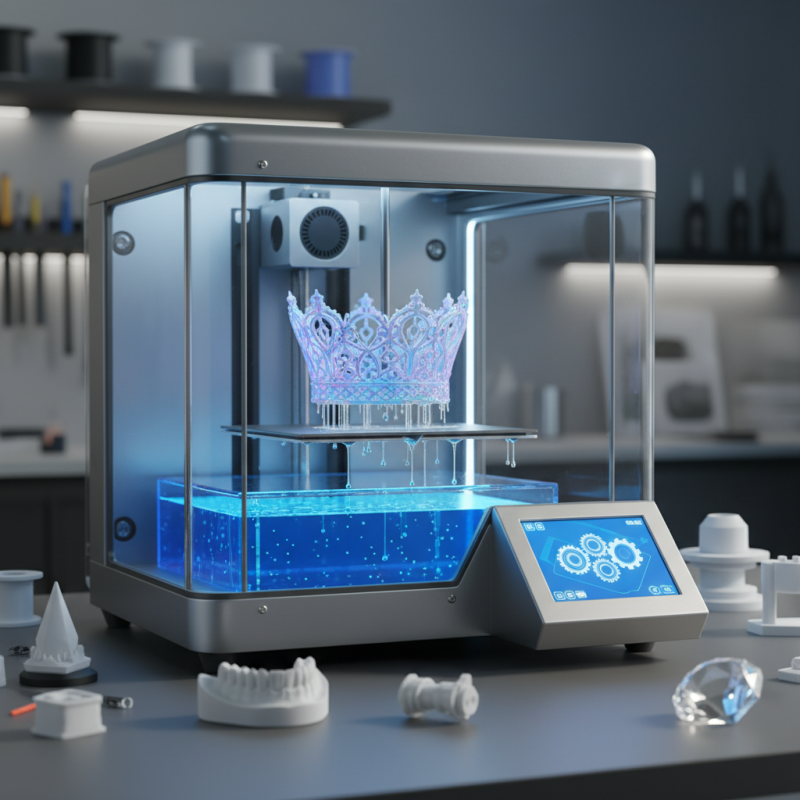

3D resin printing technology has transformed the way we approach prototyping and manufacturing, offering unparalleled precision and detail in the creation of intricate designs. Unlike traditional filament-based 3D printers, which extrude melted plastic, resin printers utilize a process called stereolithography (SLA) or digital light processing (DLP). This involves curing liquid resin layer by layer with ultraviolet light, resulting in models that boast fine details and smooth finishes, making it ideal for applications in jewelry design, dental modeling, and miniatures.

One of the major advantages of 3D resin printing is its ability to produce highly accurate and complex geometries that would be challenging or impossible to achieve with other printing technologies. The fine resolution of resin printers allows for sharp edges and intricate patterns, which increases the overall quality of the final product. Additionally, this technology often requires less post-processing compared to other methods, as the printed items can emerge with a polished surface that demands minimal sanding or finishing. As a result, 3D resin printing is rapidly gaining traction among professionals and hobbyists alike, opening up new possibilities for innovation and creativity in the realm of digital fabrication.

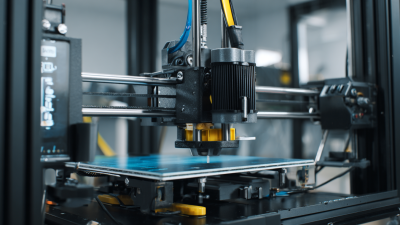

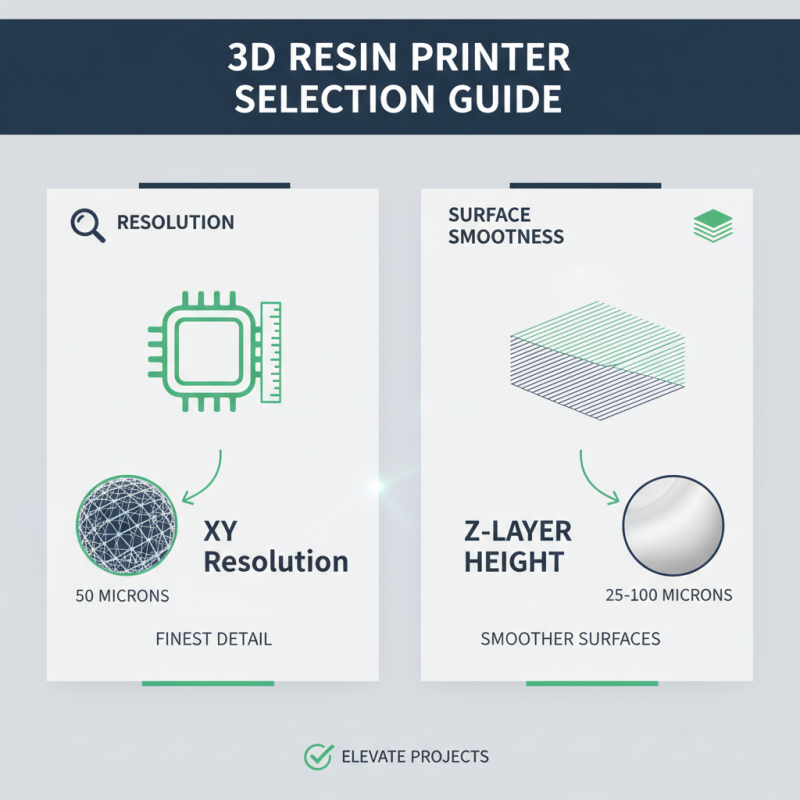

When selecting a 3D resin printer, understanding key features can substantially elevate your projects' precision and quality. First on the list is resolution. Printers are typically categorized by their XY resolution, often measured in microns, which directly influences the level of detail in printed models. According to market research, high-resolution printers can achieve an XY resolution as fine as 50 microns, which is vital for intricate designs. Consider also the Z-layer height, which affects vertical resolution; a smaller layer height results in smoother surfaces but takes longer to print.

Another critical feature is the printer's build volume. If you plan on creating larger models, it’s essential to choose a printer that accommodates your size requirements. Understanding the trade-off between build volume and resolution will help you make informed decisions based on your project's needs. The best printers currently available offer a variety of build dimensions, which can range from compact sizes suitable for small figurines to expansive volumes for larger sculptures.

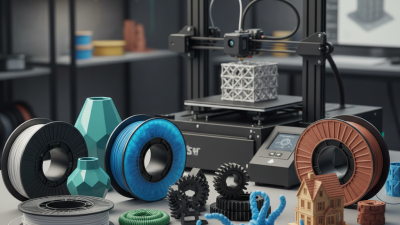

Tips: Always check user reviews and performance benchmarks that detail real-world printing experiences. Furthermore, consider investing in a printer that offers easy access to servicing and support, as ongoing maintenance can greatly impact your printing results. Lastly, look into the material compatibility of the printer, ensuring it can work with various resin types to maximize creativity in your projects.

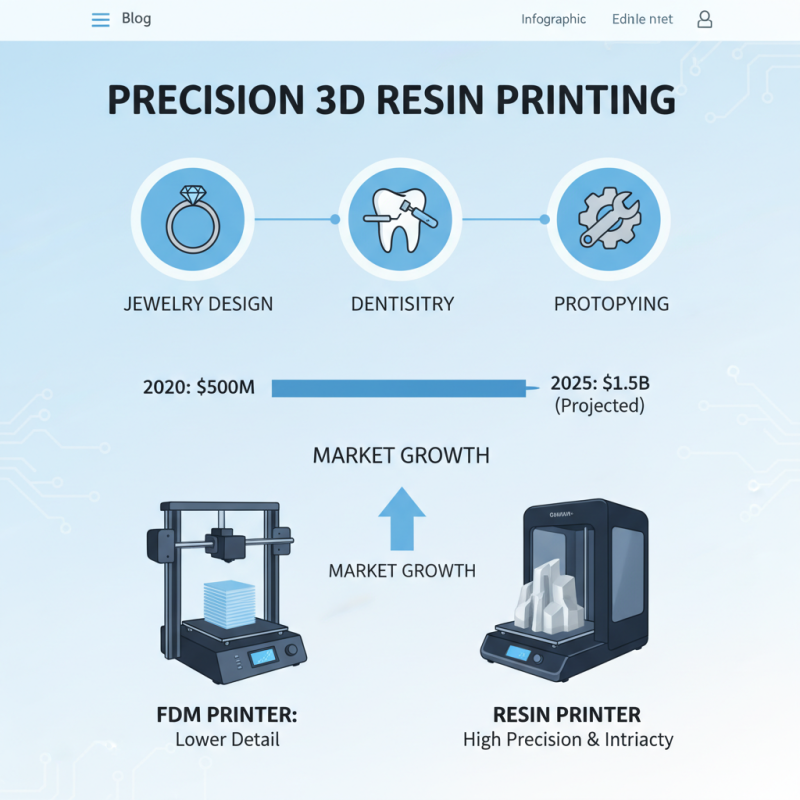

When it comes to 3D printing, the precision and quality of the final product are paramount, particularly in industries such as jewelry design, dentistry, and prototyping. Recent industry reports highlight that the demand for high-precision 3D resin printers is expected to grow significantly, with the market projected to reach approximately $1.5 billion by 2025. This growth is driven by the ability of resin printers to produce detailed and intricate designs that surpass the capabilities of traditional FDM printers.

Top-rated 3D resin printers offer a range of features that enhance accuracy and detail. Statistically, printers with a higher resolution capability—measured in microns—can achieve finer details, making them ideal for applications requiring exceptional intricacy. For instance, models with resolutions below 50 microns are increasingly popular among professionals seeking to push the boundaries of design, as they ensure smooth surfaces and precise geometries. Additionally, advancements in UV light technology and exposure times contribute to the efficiency and effectiveness of resin printing processes, providing users with greater control over the quality of their prints.

Investing in a high-quality 3D resin printer can significantly impact the outcomes of various projects, allowing for rapid prototyping and production with stunning results. As the landscape of 3D printing continues to evolve, those seeking to elevate their work should prioritize precision and quality in their equipment choices, cultivating an environment where creativity and technology collaborate seamlessly.

When exploring the current market for 3D resin printers, precision and quality stand out as pivotal factors for production. A recent report by the Wohlers Associates 2021 Additive Manufacturing Industry Report highlighted that the resin printing segment has seen a remarkable increase in adoption, rising by over 35% in the last year alone. This surge is due to the technology's ability to create intricate details and smooth surfaces that traditional FDM printers may struggle to achieve. Specifically, many professionals in sectors like jewelry design and dental modeling are leveraging high-resolution resin printers to bring their projects to life with unmatched fidelity.

Furthermore, a comparative analysis of popular 3D resin printers indicates significant advancements in build speed and accuracy. For instance, printers with monochrome LCD screens offer up to 50% faster printing times compared to their color LCD counterparts, without sacrificing detail. According to research by SmarTech Analysis, the market for high-resolution 3D printing is projected to rise substantially, indicating a shift towards devices that maximize both efficiency and quality. Key metrics such as layer resolution, printing speed, and ease of resin management are critical to consider when selecting a 3D resin printer, as they greatly influence the end result of a project.

| Feature | Printer 1 | Printer 2 | Printer 3 |

|---|---|---|---|

| Price | $199 | $299 | $499 |

| Build Volume | 120 x 68 x 170 mm | 130 x 130 x 180 mm | 200 x 200 x 300 mm |

| Layer Resolution | 10 - 100 microns | 20 - 100 microns | 25 - 50 microns |

| Print Speed | 30 mm/hour | 40 mm/hour | 60 mm/hour |

| Connectivity | USB, Wi-Fi | USB | Ethernet, USB |

| User Rating | 4.2/5 | 4.5/5 | 4.7/5 |

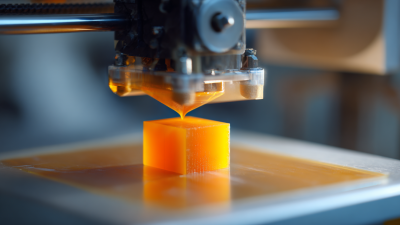

Resin printing has revolutionized the way makers and artists create intricate designs, with its ability to achieve stunning precision and detail that traditional printing methods struggle to match. To ensure optimal printing results with 3D resin printers, it's essential to adhere to best practices throughout the printing process. According to industry studies, approximately 70% of print failures can be traced back to improper resin handling and incorrect printer settings. Therefore, understanding the nuances of resin properties and printer calibration becomes key to successful projects.

Tip: Always shake or stir your resin before use to ensure a consistent mixture, as separation can lead to failed prints. Moreover, maintaining a clean printing environment drastically reduces contamination risks, which can affect print quality. Check the printer's settings such as layer height and exposure time based on the resin manufacturer’s recommendations; these settings can significantly influence the curing process and overall final output quality.

Another vital aspect of achieving high-quality resin prints is post-processing. Supporting structures and the removal of excess resin not only refine the final piece but also enhance its durability. An industry report shows that properly cured resin prints can exhibit over 90% improved strength when compared to rushed or improperly cured prints. Implementing thorough washing and curing methods will elevate your prints to professional standards, ensuring that each project stands out with remarkable quality and precision.