In the ever-evolving realm of 3D printing, achieving professional-quality prints often depends on the materials used, and one standout option is High Wax Resin for 3D Printers. This specialized resin has garnered attention for its unique properties that cater to intricate designs and detailed finishes. According to renowned 3D printing expert Dr. Lisa Wang, “The precision and smoothness offered by High Wax Resin can transform the creative process, enabling artists and designers to fully realize their visions.”

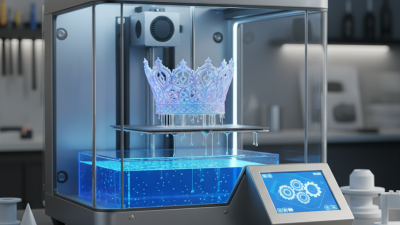

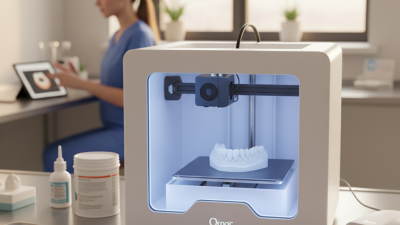

As the demand for high-quality prototypes and bespoke models increases, High Wax Resin for 3D Printers presents itself as an indispensable tool. Its low viscosity allows for exceptional detail capture, making it perfect for applications where precision is paramount, such as jewelry making and dental molds. With the right understanding of its capabilities and best practices, users can elevate their 3D printing projects to unprecedented levels of professionalism.

This article aims to explore the nuances of selecting the best High Wax Resin for 3D Printers, providing insights that can guide both amateurs and seasoned professionals in their pursuit of excellence in 3D printing. By delving into the essential features and recommendations, we hope to empower users to make informed choices that will enhance their printing experiences and outcomes.

High wax resin has emerged as a popular choice in the world of 3D printing, particularly for those aiming to achieve professional-quality prints. One of the primary benefits of using high wax resin is its exceptional detail resolution, allowing for intricate designs and fine features to be reproduced accurately. This characteristic makes it ideal for applications such as jewelry making and dental models, where precision is paramount. The smooth finish that high wax resin provides also enhances the overall aesthetic of the final product, reducing the need for extensive post-processing.

When working with high wax resin, it’s important to consider the curing process. Ensure that your printer is calibrated correctly for optimal results, as improper settings can lead to underexposed or overexposed prints. It is also advisable to work in a well-ventilated area, as resin materials can emit fumes that may be harmful if inhaled.

Another tip for using high wax resin is to take advantage of its excellent flow properties. This allows for smoother dispensing and reduced chances of air bubbles, which can affect print quality. Regularly cleaning your printer and using fresh resin can further enhance the performance, ensuring that your prints maintain their professional quality with every project you undertake.

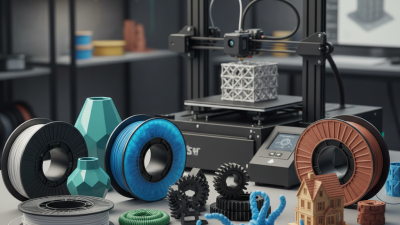

When selecting the right high wax resin for your 3D printing projects, it's essential to consider several key factors that can impact the final quality of your prints. First, the viscosity of the resin plays a crucial role in determining how well the material flows and fills the intricate details of your model. A lower viscosity resin is generally easier to work with, allowing for smoother prints with high-definition features. Additionally, consider the curing time of the resin, as faster curing can significantly speed up the printing process, allowing for efficiency without sacrificing quality.

Tips for choosing the right high wax resin include evaluating the specific requirements of your project, such as flexibility, durability, and surface finish. If your prints require intricate details, opt for a resin that emphasizes high detail, which will help capture finer elements. It's also beneficial to read reviews and seek recommendations based on the experiences of other users, as this can provide insights into performance and usability. Lastly, always conduct small test prints to assess compatibility with your printer settings and optimize your results before committing to larger projects.

| Resin Type | Viscosity (cP) | Color | Cure Time (seconds) | Shore Hardness | Applications |

|---|---|---|---|---|---|

| High Wax Resin A | 300 | Translucent Yellow | 8 | 80D | Jewelry, Miniatures |

| High Wax Resin B | 350 | Opaque White | 10 | 75D | Figurines, Art Pieces |

| High Wax Resin C | 280 | Clear | 6 | 82D | Molds, Prototypes |

| High Wax Resin D | 320 | Dark Blue | 12 | 78D | Dental, Industrial Parts |

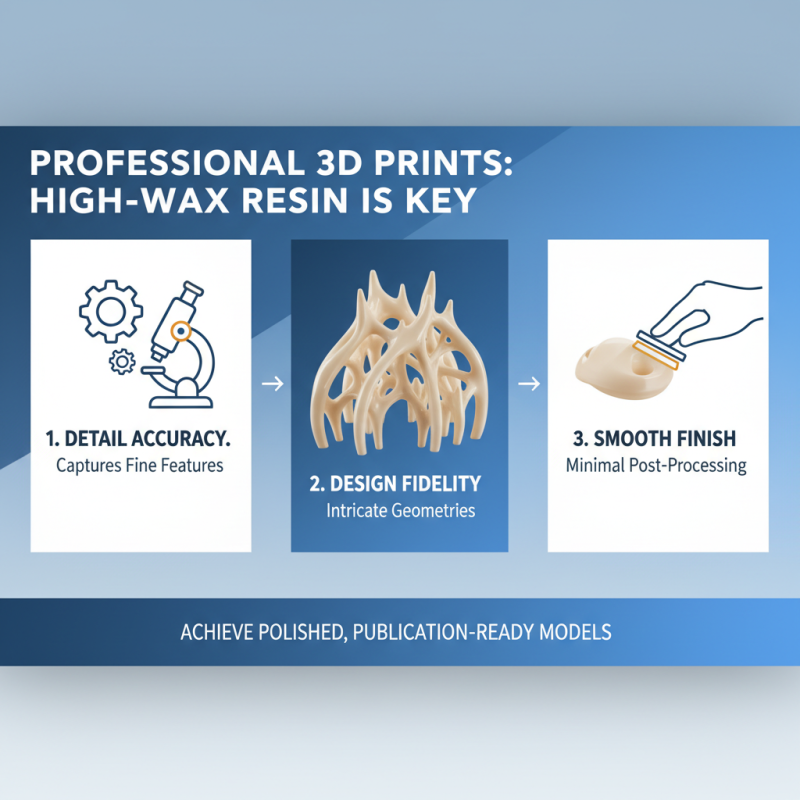

When it comes to achieving professional quality prints with 3D printers, the choice of high wax resin is crucial. One of the key characteristics of professional quality prints is detail accuracy. High wax resin offers excellent fidelity to the original design, capturing fine features and intricate geometries that are essential for creating visually appealing models. The smooth finish that high wax resins provide also minimizes post-processing efforts, making it easier to achieve a polished appearance right off the printer.

Another important characteristic is the ability to create durable and stable prints. Professional quality prints should withstand handling and environmental factors without deforming. High wax resins usually exhibit enhanced mechanical properties, ensuring that prints maintain their shape and integrity over time. This durability is particularly critical for applications in jewelry making or dental modeling, where precision and longevity are paramount.

Tips: To maximize the performance of high wax resin, ensure your printer settings are optimized for the specific type of resin being used. Consider experimenting with different layer heights and exposure times to fine-tune the balance between detail and printing speed. Additionally, maintaining a clean printing environment and proper storage of the resin can further enhance print quality and consistency.

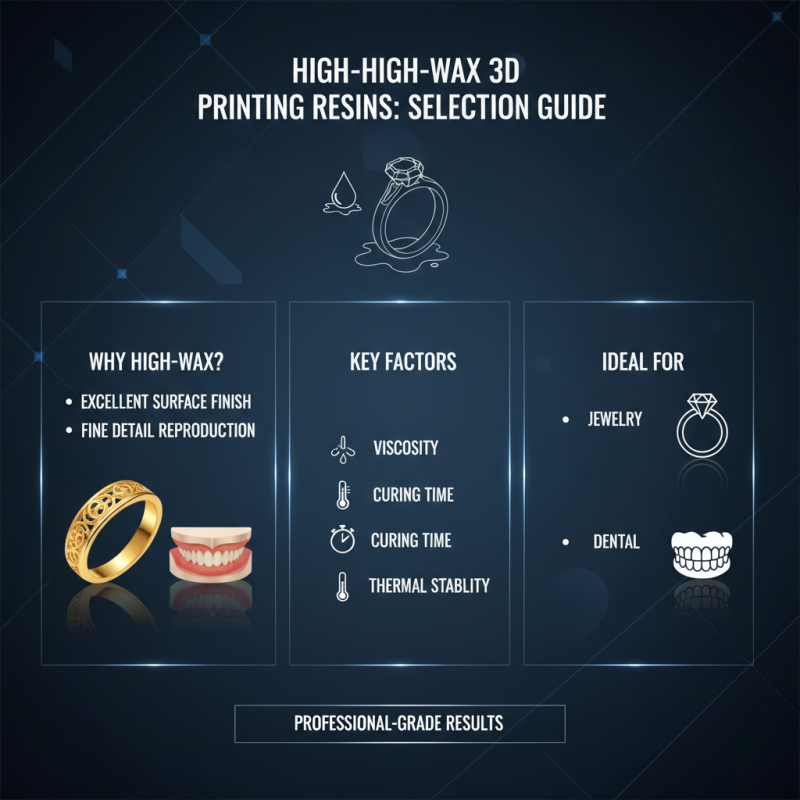

When selecting the best high wax resins for 3D printing, it is essential to conduct a comparative analysis of the available options to ensure professional-grade results. High wax resins stand out due to their excellent surface finish and fine detail reproduction, making them ideal for industries such as jewelry making and dental applications. Key factors to consider include viscosity, curing time, and thermal stability, as these elements significantly impact the printing process and the quality of the final product.

In this comparative analysis, one must evaluate resins based on their performance characteristics and print reliability. Some resins may offer faster curing times, which can enhance productivity, while others may provide superior detail resolution, crucial for intricate designs. Furthermore, the ability to achieve a smooth surface finish is vital as it minimizes post-processing requirements. When assessing these high wax resins, it's also important to consider their compatibility with various 3D printers and the specific use cases in which they excel, ultimately guiding users toward making informed decisions for their printing projects.

When working with high wax resin for 3D printing, achieving optimal results requires careful attention to several factors. First and foremost, the print settings must be fine-tuned for the specific resin being used. This includes adjusting settings such as layer height, exposure time, and lift speed to ensure that each layer adheres properly while minimizing the risk of defects. Conducting test prints can help determine the ideal parameters for achieving smooth finishes and intricate details.

Another critical aspect is the curing process. Proper post-processing is essential for high wax resin prints, as it significantly affects the final quality. After printing, it is important to wash the prints thoroughly to remove any uncured resin. Following the wash, curing the prints with UV light ensures that the resin hardens completely, enhancing the strength and durability of the final product. Additionally, allowing prints to rest for a short period before final curing can help achieve a smoother surface finish, which is particularly important for professional-grade applications. By following these tips, you can maximize the potential of high wax resin, resulting in stunning, professional-quality prints.