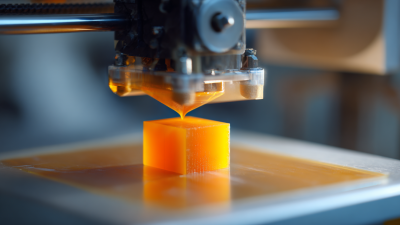

In the ever-evolving world of 3D printing, the choice of materials plays a pivotal role in determining the quality and effectiveness of the final product. Among these materials, **Resin For 3D Printers** has gained significant attention for its ability to produce intricate details and smooth finishes that traditional filament cannot match. According to a report by MarketsandMarkets, the global market for 3D printing materials, including resins, is projected to reach USD 3.2 billion by 2026, indicating a robust growth trajectory fueled by advancements in technology and increasing industry applications.

Expert in 3D printing technologies, Dr. Emily Chen, notes, “The right resin can dramatically enhance the capabilities of your 3D printer, unlocking new design possibilities and improving the overall user experience.” This sentiment reflects the growing recognition within the industry that selecting the best resin is critical for achieving superior results, whether for prototyping, manufacturing, or creative projects. As we explore the top five resins that can elevate your 3D printing experience, we will delve into their unique properties and applications, ultimately guiding enthusiasts and professionals alike towards making informed choices in their printing endeavors.

In 2025, the landscape of 3D printing continues to evolve dramatically, especially in the realm of resin selection. The right resin can significantly enhance print quality, resulting in sharper details, smoother surfaces, and greater durability of the printed items. Industries are witnessing innovative applications of resin, such as in the development of recoil pads for firearms, where custom topological designs mitigate recoil effects. This intersection of technology and design not only highlights the versatility of resins but also their capability to push boundaries in product refinement.

When choosing a resin for your 3D printer, consider the specific needs of your projects. For high-detail prints, opt for resins designed for fine features and low shrinkage, which help maintain accuracy during the printing process. Additionally, experimenting with resins reinforced with composites can improve mechanical properties and open up new functionalities, which is increasingly crucial as the demand for specialized 3D-printed products rises.

Tips: Always test different resin types to find which best suits your application, and ensure proper ventilation as many resins can emit harmful fumes. Regularly clean your printer's components to avoid any build-up of resin residue, which can affect print quality and machine performance.

When choosing the right resin for 3D printing, understanding the mechanical properties of strength and flexibility is crucial. Resins appear in a variety of formulations, each designed to meet specific requirements. For items needing durability and robustness—like functional prototypes or parts that endure mechanical stress—high-strength resins are essential. On the other hand, flexible resins offer a unique advantage when creating parts that require bending or compressing without breaking, which is ideal for items like phone cases or wearable devices.

Tips: Always review the technical data sheets provided by manufacturers to compare the tensile strength and elongation at break metrics of various resins. This will help you select the right resin that aligns with your project needs.

Additionally, consider how the print's end-use will impact your resin choice. For example, if you’re printing a component that will face constant movement or flexing, opt for a flexible resin to prevent breakage over time. Conversely, for applications that demand precision and resistance to wear, a high-strength resin may be the better option.

Tips: Experimenting with different resin types on smaller print jobs can provide insight into how they perform under realistic conditions, helping you make an informed decision for larger projects.

When it comes to elevating your 3D printing experience, understanding the cure times and layer adhesion of different resins is crucial.

Cure times can significantly impact your workflow; faster curing resins may streamline the printing process, allowing for quicker project turnarounds. However, it's essential to strike a balance, as overly quick curing can lead to challenges in layer bonding, potentially compromising the structural integrity of the final print. Therefore, selecting a resin that provides adequate working time without sacrificing speed is vital for optimal performance.

Layer adhesion is another key factor in achieving high-quality 3D prints. Resins with superior layer adhesion ensure that each layer bonds effectively, resulting in prints that are not only more durable but also exhibit fine details and smooth surfaces. Some advanced resins are formulated to enhance adhesion properties, thus minimizing the risk of delamination between layers. Evaluating these characteristics is essential for anyone looking to achieve professional-grade results, making the choice of resin not just an aesthetic decision but a fundamental one for the overall effectiveness of your 3D printing projects.

When choosing the best resin for 3D printing, understanding the cost-effectiveness of various options is crucial for both hobbyists and professionals. Resins can range significantly in price, with some high-end options offering exceptional detail and durability, while others may provide sufficient quality for less demanding applications at a fraction of the cost. Hobbyists may prioritize budget-friendly resins that still deliver acceptable results for projects like prototypes and figurines, allowing them to experiment without a large financial commitment.

On the other hand, professionals often seek resins that not only enhance the final product's aesthetics but also offer superior mechanical properties. These premium resins might come with a higher price tag, but their benefits, such as faster printing times, higher resolution, and better post-processing ease, often justify the expense. A comparative analysis of these resins helps users identify which products align best with their specific needs and budgets, ensuring a rewarding printing experience that optimizes both investment and output quality.

| Resin Type | Print Quality | Curing Time (mins) | Cost per Liter ($) | User Level |

|---|---|---|---|---|

| Standard Resin | High | 15 | 30 | Hobbyist |

| Transparent Resin | Very High | 20 | 40 | Professional |

| Flexible Resin | Medium | 25 | 50 | Advanced Hobbyist |

| Castable Resin | High | 30 | 75 | Professional |

| Durable Resin | High | 18 | 60 | Professional |

As the demand for 3D printing grows, so does the necessity for sustainable materials. Eco-friendly resins are becoming increasingly popular in the 3D printing community, demonstrating that it is possible to merge creativity with environmental responsibility. These alternatives are often derived from plant-based sources, which significantly reduce the carbon footprint compared to traditional petroleum-based resins. Selecting eco-friendly materials not only benefits the environment but can also lead to safer print experiences with fewer harmful emissions.

When transitioning to **sustainable resins**, consider a few key tips. Firstly, verify the certifications of the resin to ensure it meets eco-friendly standards. Secondly, experiment with different brands to find one that offers a balance of print quality and environmental impact. Lastly, ensure proper disposal of your waste materials; many eco-resins are designed to break down more easily than conventional ones, but proper recycling practices can further enhance sustainability.

Embracing these eco-friendly options does not mean compromising on quality or performance. The advancements in resin technology are making it easier than ever to find high-quality materials that deliver exceptional results while contributing to a healthier planet. By supporting sustainable practices, you can enhance your 3D printing experience and play a role in making the industry more environmentally conscious.