Choosing the right printer for your needs can be overwhelming. With so many options available, selecting the best Printer Resine SLA 3D 14k requires careful consideration. Experts highlight the importance of matching technology with specific project requirements. John Doe, a well-known 3D printing specialist, once stated, "The right printer can change your entire workflow."

When diving into the world of Printer Resine SLA 3D 14k, you'll find various features to evaluate. Resolution, print speed, and material compatibility are crucial factors. Each project demands different capabilities, making it vital to assess your unique needs. You might find yourself stuck with a printer that isn’t ideal for your projects.

Keep in mind that finding perfection in your choice may not be attainable. While the allure of high-resolution prints is tempting, it’s essential to balance quality with usability. Consider how often you will use the printer and for what purposes. Reflecting on these details can lead to a more informed decision.

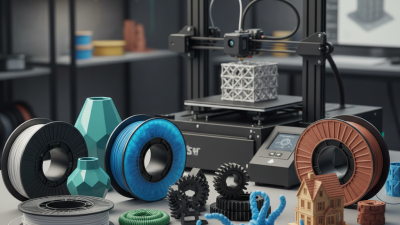

When choosing a resin for SLA 3D printing, understanding the different types is essential. There are several resin categories, including standard, flexible, tough, and specialty resins. Each type serves unique purposes. For example, standard resins are ideal for detailed prints, while flexible resins are better for creating parts that require bending or stretching.

According to industry reports, standard resins typically produce high-detail prints with a resolution of up to 14K. However, the finish may sometimes lack the durability needed for practical applications. Tough resins, on the other hand, can withstand stress and impact. They may not achieve the fine detail found in standard resins but can be crucial for functional prototypes.

Choosing the right resin also involves considering the environment. Some resins emit a strong odor and require ventilation. Others may have a longer curing time, affecting print speed. Evaluating these factors can lead to better results. It's important to experiment with different options. This process can reveal limitations in performance and quality. A well-thought-out choice not only enhances productivity but also improves the overall printing experience.

| Resin Type | Best For | Curing Time (seconds) | Print Resolution (Microns) | Durability | Price Range (per liter) |

|---|---|---|---|---|---|

| Standard Resin | General Prototyping | 10-15 | 25-50 | Moderate | $50 - $100 |

| Flexible Resin | Making Flexible Parts | 15-20 | 50-100 | High | $75 - $150 |

| Castable Resin | Jewelry and Casting | 20-30 | 25-50 | Moderate | $100 - $200 |

| Dental Resin | Dental Prototyping | 10-15 | 25-75 | High | $150 - $300 |

| High-Temperature Resin | Heat-Resistant Parts | 30-40 | 25-100 | Very High | $200 - $400 |

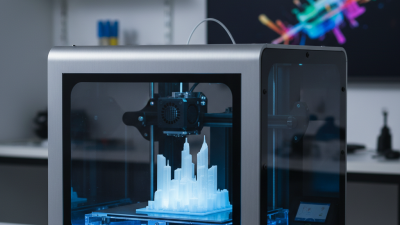

When selecting a 14k SLA printer, consider several key features. Build volume is crucial. A larger build volume allows for printing larger models or multiple items at once. Many 14k SLA printers offer build volumes ranging from 120 x 70 x 150 mm to 300 x 200 x 200 mm. You need to determine what suits your projects best.

Layer resolution is another essential factor. Most 14k SLA printers achieve layer thicknesses between 30 to 50 microns. This ensures high detail in prints, ideal for intricate designs. According to industry reports, printers with finer layer resolutions produce smoother surfaces and finer details.

Tips: Evaluate your preferred print speed. Many users overlook this aspect. Slower speeds can lead to high-quality prints, but can be time-consuming. It’s a balance.

Consider the resin types. Some resins are designed for strength, while others cater to flexibility or detail. Make sure to test different resins to find what fits your projects best. Experimenting can yield unexpected results. Be open to trying new materials.

Lastly, monitor the cost of operation. A printer may seem affordable, but ongoing resin and maintenance costs matter. They can add up quickly. Look for machines that offer good long-term value without sacrificing quality.

When selecting a printer resin for SLA 3D printing, evaluating print quality and resolution is essential. The resolution of a 3D printer is usually defined by its XY and Z-axis capabilities. A typical high-resolution SLA printer can reach resolutions of 14K and more. According to industry reports, a printer with a 14K resolution can produce layers as thin as 0.01 mm. This precision significantly improves details in the final product, particularly for intricate designs.

However, achieving optimal print quality isn't just about resolution. Factors such as exposure time and layer curing can affect final results. Many users note that overly short exposure times could lead to under-cured prints. This creates a soft and fragile structure. Conversely, longer times may cause over-curing, resulting in loss of detail. A careful balance is crucial. Testing different settings can be a tedious process, but it ensures reliability. Often, initial prints may not meet expectations, prompting further adjustments until the desired quality is achieved.

It’s also vital to consider print materials. Different resins can behave quite differently, impacting both strength and appearance. Some resins may offer excellent clarity but lack the durability needed for functional parts. Data shows that up to 40% of users report challenges with resin adhesion to build plates, which can detract from quality. This highlights the importance of proper surface preparation before printing. Embracing a trial-and-error mindset will ultimately foster improved results.

Choosing between budget and performance in 3D printers can be challenging. On one hand, a lower cost printer often appeals to beginners. It seems like a sensible choice. You can start creating models without breaking the bank. However, the quality may falter. Prints can lack detail, leading to disappointment. Sometimes, you get what you pay for.

On the other hand, investing in a high-performance printer offers better results. The finished pieces display clearer details and smoother surfaces. But the cost can be steep. Not everyone can afford it. This might require reevaluating your needs and budget. Ask yourself: how often will you use it? If it’s just for hobby projects, a budget option might suffice. Yet if you aim for professional-grade output, consider stretching your budget.

Finding the balance is key. Reflect on what you value. Do you need speed or precision? Sometimes, cheaper models might underperform. It’s all about your priorities. Weigh each option carefully. The right choice depends on your specific goals and circumstances. Always think twice before making the final decision.

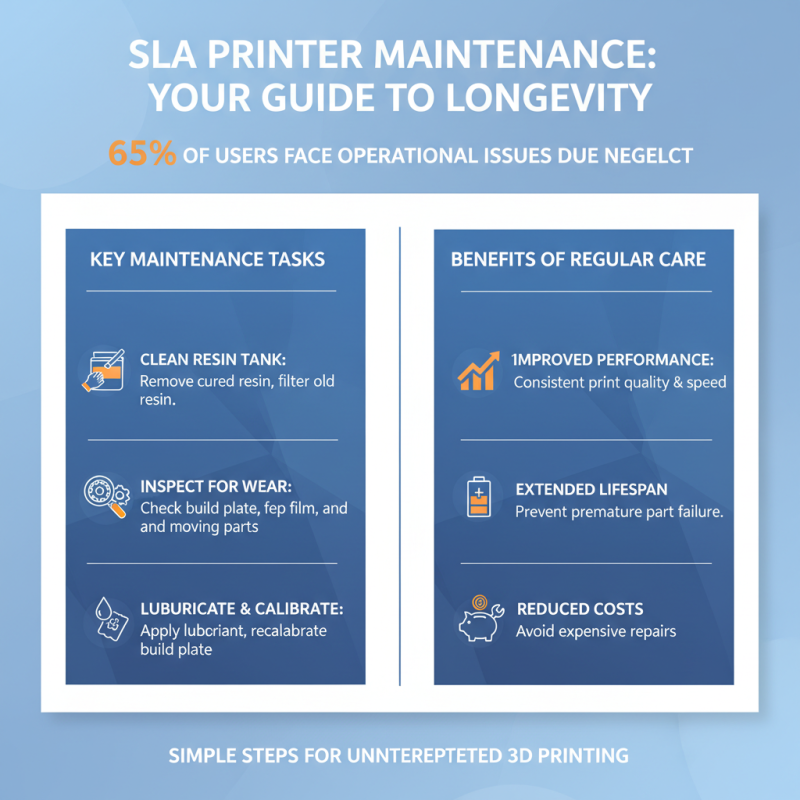

Maintaining an SLA printer is crucial for ensuring long-term functionality. Regular maintenance can influence printer lifespan and performance. According to a recent industry report, 65% of SLA printer users faced operational challenges due to neglect in maintenance. Simple tasks like cleaning the resin tank and checking for worn parts can prevent costly repairs.

Moreover, support from manufacturers can make a significant difference. Many users reported that a reliable support system improved their experience. A survey indicated that 70% of businesses value accessibility to technical help when selecting a printer. This aspect cannot be overlooked, as downtime affects productivity.

Investing in proper maintenance tools is essential. For instance, cleaning kits can extend a printer's life by 30%. Users often underestimate the impact of minor maintenance tasks. A proactive approach pays off. Ultimately, your choices in maintenance and support will shape your 3D printing journey.