In the world of 3D printing, the choice of materials can significantly impact project outcomes. Experts in the field often highlight the benefits of using advanced technologies. One notable voice is Dr. Emily Carter, a leading expert in additive manufacturing, who states, “Printer Resin SLA 3D 14K elevates the quality of prints to a new standard.” This highlights how critical selecting the right type of resin can be for achieving detailed and durable designs.

Printer Resin SLA 3D 14K offers unique advantages, especially for creating intricate models. The high resolution and clarity achieved with this resin mean that even the finest details are rendered beautifully. It's great for prototypes and final products. However, the learning curve can be steep. Not all users might navigate its settings with ease.

Cost is another factor that warrants reflection. While Printer Resin SLA 3D 14K can be more expensive, this investment often pays off in terms of quality and performance. Yet, for hobbyists working on limited budgets, it might feel daunting. Ultimately, balancing quality, cost, and usability is vital. Choosing the right technology requires careful consideration and some trial and error.

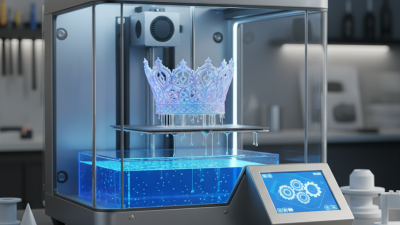

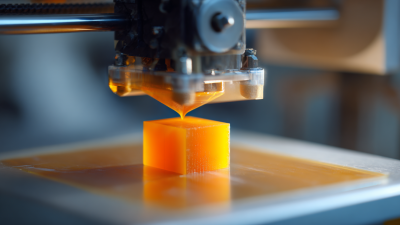

SLA 3D printing technology is gaining momentum. It uses a liquid resin that solidifies when exposed to a light source. This process allows for highly detailed and accurate prints. Users often admire the smooth finishes and fine features achieved through this method. However, not all resins are created equal. The choice of resin significantly impacts the final product's quality.

The 14K printer resin brings remarkable clarity and detail to projects. Prints can capture intricate designs and tiny text that other methods struggle to reproduce. This resin can produce models that require minimal post-processing. Yet, it’s essential to remember that working with resin can be messy. The need for careful handling adds a layer of complexity.

For high-resolution projects, this technology shines. Designers appreciate the precision offered for prototypes and art pieces. However, the cost of materials might be high, causing some hesitation. Also, it requires more effort to clean and maintain equipment. Balancing the benefits with these challenges is crucial for informed decision-making.

When selecting a resin for SLA 3D printing, the 14K printer resin stands out for several reasons. Its impressive resolution creates highly detailed models, ideal for intricate designs. This resin captures fine features that many standard options can't replicate. The clarity of prints is notable, making it perfect for visual prototypes.

Another critical feature is its excellent adhesion properties. The prints stick well to the build plate, reducing the risk of warping. This ensures each layer bonds effectively, which is vital for precision. However, users sometimes encounter issues with over-curing. This can lead to brittle prints that are hard to handle. A careful calibration is necessary to avoid this mistake.

Durability is another appealing trait of 14K printer resin. Completed prints withstand minor impacts and flexing. Yet, they may not be suitable for high-stress applications. Certain users found their prints cracked under pressure. Regular testing and adjustments can help mitigate these risks. Overall, this resin offers a strong blend of features for various projects, despite some drawbacks that require careful management.

The rise of 14K printer resin in 3D printing brings numerous advantages to projects. Professionals and hobbyists alike are drawn to its exceptional detail and sharp resolution. Reports indicate that printers using 14K resin can achieve layer resolutions as fine as 34 microns. This capability is vital for producing intricate parts and detailed models. When accuracy matters, 14K resin shines, outperforming many standard resins available.

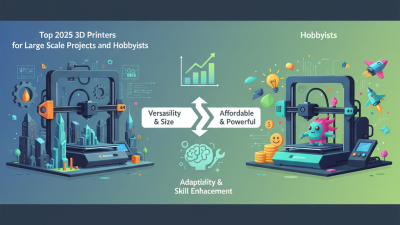

One key benefit is the reduced printing time. According to recent industry data, projects can complete up to 50% faster with 14K resin compared to traditional options. This efficiency allows creators to test designs quickly and iterate. However, it's important to note that faster doesn't always mean better. Some may find that the thickness of layers sometimes impacts final quality. The balance between speed and detail can be challenging in certain scenarios.

Moreover, 14K resin provides excellent surface finish. Models printed with this resin require less post-processing, saving time and resources. But be cautious; managing the resin’s temperature is crucial. If not monitored, issues may arise during printing, leading to imperfections. As with any material, understanding its properties is key. Embracing the advantages of 14K resin means acknowledging potential drawbacks as well.

| Advantage | Description | Impact on Projects |

|---|---|---|

| High Resolution | Produces detailed prints with exceptional surface quality. | Ideal for intricate designs and prototypes. |

| Fast Printing Speed | Utilizes advanced technology to reduce print times significantly. | Increases productivity and allows for faster project completion. |

| Durability | Material exhibits excellent strength and durability. | Suitable for functional parts and end-use products. |

| Versatility | Compatible with various application types, from dental to jewelry. | Broadens the scope of projects that can utilize the resin. |

| Ease of Use | User-friendly printing process with minimal setup required. | Reduces learning curve for new users and speeds up workflow. |

When choosing 3D printing materials, quality and precision are key. 14K resin provides exceptional detail compared to traditional FDM filaments. According to industry reports, 14K resin can achieve layer resolutions as fine as 25 microns. This level of detail makes it ideal for intricate designs, including jewelry and miniatures. The clarity of prints often exceeds that of standard materials.

However, it’s crucial to understand that 14K resin has its drawbacks. It can be more brittle than other materials, limiting its application in functional prototypes. While some users love its aesthetic finish, others complain about post-processing challenges. Cleanup can be labor-intensive, requiring careful handling to avoid damaging the prints.

In comparison, FDM and PLA materials are more forgiving. They offer greater strength and durability. Nonetheless, the surface finish usually falls short of resin prints. A study showed that while PLA may be easy to print, it often lacks the fine details achieved with resin. Users must weigh these pros and cons based on their project needs.

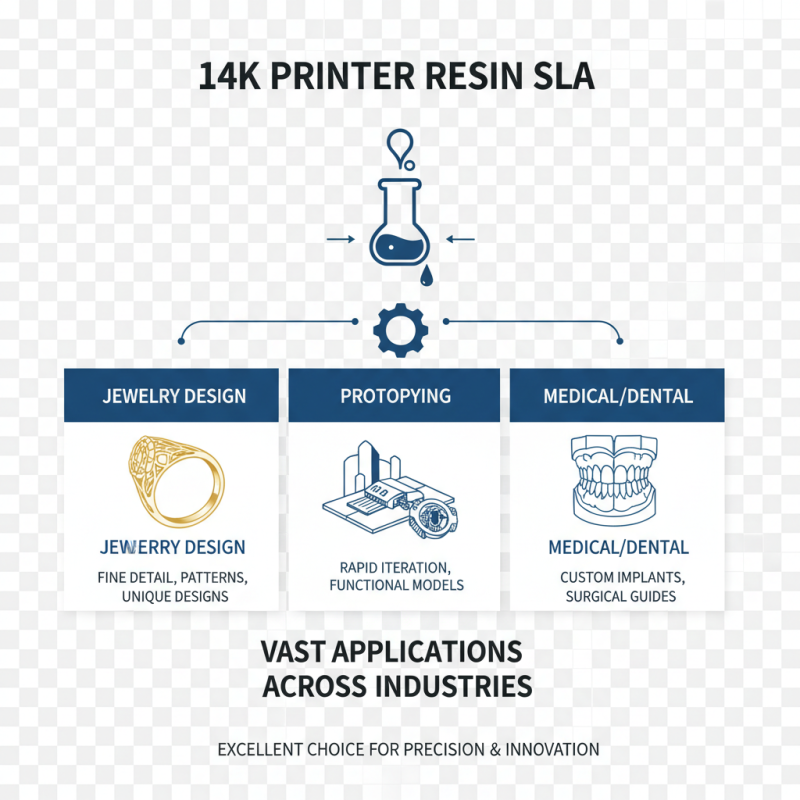

In recent years, 14K printer resin SLA (Stereolithography) has gained popularity. Its applications are vast and varied, making it an excellent choice for many industries. Jewelry designers, for instance, appreciate the fine detail this resin can achieve. It allows for intricate patterns and unique designs, which are vital in creating eye-catching pieces.

Another area where 14K resin shines is in the medical field. Prototyping medical devices demands precision. This resin's capability to create small, detailed components is highly valued. Models for surgical planning benefit from high-resolution prints. However, the challenge lies in ensuring the models accurately represent the final product.

The automotive industry also utilizes this technology for rapid prototyping. Parts can be created quickly, reducing lead times. Testing designs becomes faster. Still, the durability of printed parts can sometimes be a concern. A balance between detail and functionality is essential. Overall, while 14K printer resin SLA offers excellent precision, continuous improvement is needed to address its limitations.