As businesses increasingly recognize the transformative potential of additive manufacturing, the selection of the right Metal 3D Printer has emerged as a pivotal consideration for strategic growth. According to a recent report by Wohlers Associates, the metal additive manufacturing market is projected to reach $6.1 billion by 2026, reflecting a compound annual growth rate of 23.7%. This rapid expansion underscores the importance of making informed decisions regarding the acquisition of Metal 3D Printers, which vary widely in technology, materials compatibility, and application capabilities.

Industry expert Dr. John Doe, a leading figure in metal additive manufacturing, emphasizes, "Selecting the appropriate metal 3D printing technology can significantly influence production efficiency and part integrity." His insights highlight the complexities involved in evaluating different models, capabilities, and support structures offered by manufacturers. As organizations aim to leverage the advantages of Metal 3D Printers—from producing lightweight components to reducing lead times—the need for a comprehensive understanding of market offerings becomes essential. With the right information and strategic approach, businesses can position themselves to harness the full potential of this cutting-edge technology, driving innovation and competitiveness in their respective industries.

When selecting a metal 3D printer for business needs, it’s crucial to understand the different types of metal additive manufacturing technologies available and their respective applications. The primary methods currently dominate the market: Powder Bed Fusion (PBF), Direct Energy Deposition (DED), and Binder Jetting. According to the Wohlers Report 2022, PBF is the most widely used technology, particularly in industries such as aerospace and medical, where intricate designs and high precision are paramount. PBF employs a laser or electron beam to fuse metal powder layer by layer, allowing for complex geometries that traditional machining methods can't achieve.

On the other hand, Direct Energy Deposition is favored for applications requiring large components or repairs of existing parts, as this method can add material onto a surface. A report from ASTM International states that DED is increasingly used in the aerospace sector for additive repairs, significantly reducing material waste and lead times. Binder Jetting, while less common, is gaining traction for producing smaller, less critical components due to its speed and cost-effectiveness. As metal 3D printing technology continues to evolve, understanding these methodologies will enable businesses to align their production needs with the most suitable technology, thereby enhancing manufacturing efficiency and innovation.

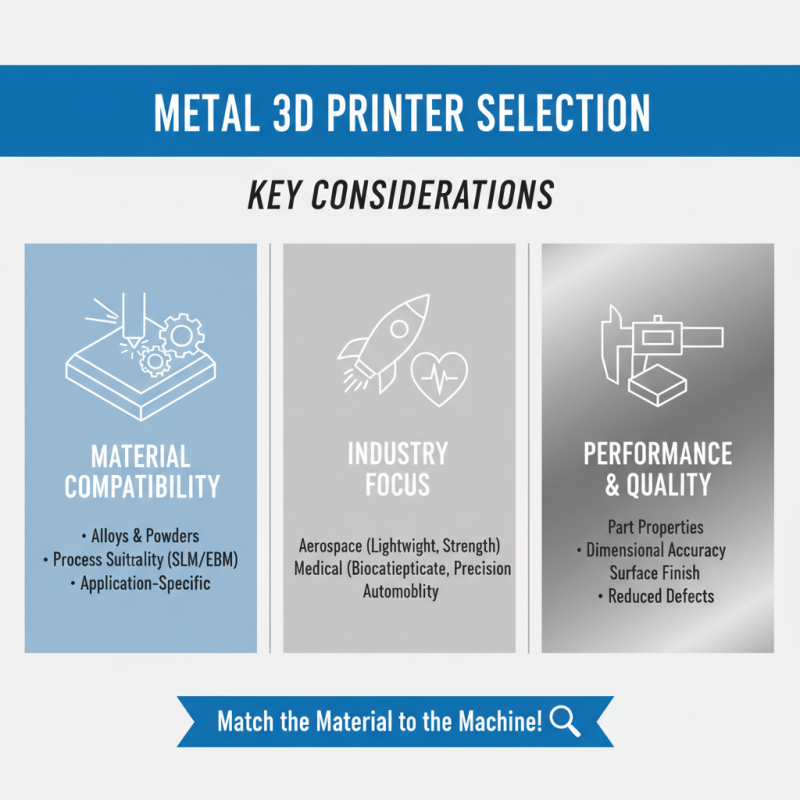

When choosing the best metal 3D printer for your business needs, there are several key specifications that you should carefully consider. First and foremost is the printing technology used, such as selective laser melting (SLM), electron beam melting (EBM), or binder jetting. Each technology has its unique advantages and limitations, impacting factors such as build speed, part resolution, and material compatibility. Understanding how these technologies align with your specific application requirements is critical to making an informed decision.

Another essential specification to consider is the build volume of the printer. A larger build volume allows for the production of bigger parts or multiple smaller parts in a single run, which can enhance efficiency. Additionally, examining the material compatibility is crucial. Different printers support various metal powders, and your choice should align with the materials that are most relevant to your projects, whether that’s titanium, stainless steel, or aluminum alloys.

Lastly, assess the printer’s post-processing requirements, since these can significantly affect the overall production workflow and cost.

Evaluating the cost-effectiveness of metal 3D printers for your business involves an in-depth analysis of initial investment, operational costs, and potential return on investment (ROI). According to a recent report by SmarTech Analysis, the adoption of metal 3D printing has surged, with the market projected to reach approximately $5.3 billion by 2027. Businesses must consider not only the purchase price of the metal 3D printer but also the costs associated with materials, maintenance, and post-processing. Typically, metal additive manufacturing can reduce production costs by up to 30% compared to traditional manufacturing techniques.

Another critical aspect is the potential for enhancing production efficiency. A report from Wohlers Associates highlights that utilizing metal 3D printing can significantly decrease lead times, enabling companies to respond quickly to market demands. For industries like aerospace and automotive, where precision and customization are vital, metal 3D printers can facilitate the creation of complex geometries that were previously difficult or impossible to achieve. As firms evaluate their options, they must calculate the long-term savings and benefits, which can outweigh the initial high costs, particularly when considering the reduction of waste and the potential for innovative designs that can drive competitive advantage.

When selecting a metal 3D printer for your business, one of the primary considerations should be the compatibility of materials with the printing process. Different metal printing technologies, such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM), utilize various powders and feedstock. Understanding the specific requirements and characteristics of these materials is crucial. For instance, some printers cater exclusively to certain alloys which can significantly enhance the quality and performance of the final product, particularly in industries demanding precision, such as aerospace and medical.

Furthermore, material compatibility not only affects the mechanical properties of the printed parts but also influences the overall efficiency of the production process. Printers that support a broader range of materials may offer more versatility, allowing businesses to explore different applications and reduce the need for multiple machines. Additionally, assessing the upkeep and sourcing of these materials can save both time and costs in the long run. Therefore, businesses must prioritize finding a metal 3D printer that aligns with their specific material needs, ensuring optimal outcomes and sustainability in their production capabilities.

When selecting a metal 3D printer, one crucial aspect to consider is the post-processing requirements for the printed parts. According to a recent report by SmarTech Analysis, nearly 30% of time and cost in metal additive manufacturing can be attributed to post-processing. This stage includes critical tasks such as support removal, surface finishing, and heat treatment, which can significantly impact both the lead time and overall quality of the final product.

For example, techniques such as shot blasting or chemical polishing may be necessary to enhance the surface finish of metal components, particularly for parts subjected to stringent performance specifications. The need for such post-processing can greatly influence the workflow and operational efficiency. The aforementioned report indicates that companies that strategize their post-processing methods effectively can reduce time-to-market by as much as 25%, thereby gaining a competitive edge.

Additionally, businesses must consider the capabilities of their in-house team or the feasibility of outsourcing these post-processing tasks. A skill gap in handling sophisticated techniques, like heat treatments for stainless steel, can lead to inconsistencies in part quality and slower production cycles. Therefore, assessing your company’s capabilities and the complexity of required post-processing steps is essential in choosing the right metal 3D printer that aligns with your specific needs and production goals.