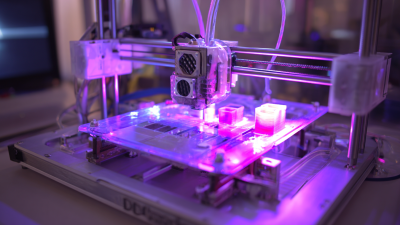

The rapid advancement of 3D printing technology has significantly expanded the materials available for various applications. Among these, PLA (Polylactic Acid) filament stands out as one of the most popular choices due to its ease of use, biodegradability, and compatibility with a wide range of 3D printers. Industry reports highlight that the global PLA filament market is expected to grow at a compound annual growth rate (CAGR) of 20% over the next few years, driven by increasing demand from sectors such as consumer goods, automotive, and healthcare.

As users delve into choosing the best PLA filament for their projects, understanding the nuances of filament properties, such as tensile strength, flexibility, and printability, becomes essential. Additionally, factors like color variety and customer reviews can significantly impact the final output. For instance, the "Anycubic PLA 3D Printer Filament" is frequently recommended for its superior quality and reliability, which further emphasizes the importance of selecting the right filament to achieve optimal printing results.

This article aims to guide users through the critical considerations when selecting PLA filament for their projects, ensuring that creators can make informed decisions that enhance the quality and efficiency of their 3D prints. As the demand for high-quality 3D printed products continues to rise, mastering the choice of filament can lead to successful outcomes in this innovative field.

When selecting the best PLA filament for your 3D printing projects, understanding its composition and properties is crucial. PLA, or Polylactic Acid, is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. This eco-friendly nature not only makes PLA a popular choice for hobbyists and professionals but also aligns with increasing environmental awareness in the 3D printing community. According to a report from the American Society of Mechanical Engineers, PLA accounts for approximately 54% of the global bioplastic market, underlining its significance and wide usage in various applications.

The properties of PLA filament add to its appeal. It boasts a low melting point, typically around 190-220°C, facilitating easier printing and reducing the likelihood of warping during the cooling phase. Furthermore, PLA exhibits good adhesion between layers and a glossy finish, which enhances the aesthetic quality of printed objects. Data from the Applied Materials industry indicates that PLA's rigidity and tensile strength make it suitable for a variety of printing applications, from prototypes to intricate models. However, it is essential to note that while PLA is strong, it is less heat-resistant than other materials, so understanding these properties can help in choosing the right filament for specific projects.

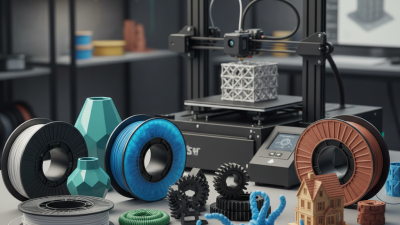

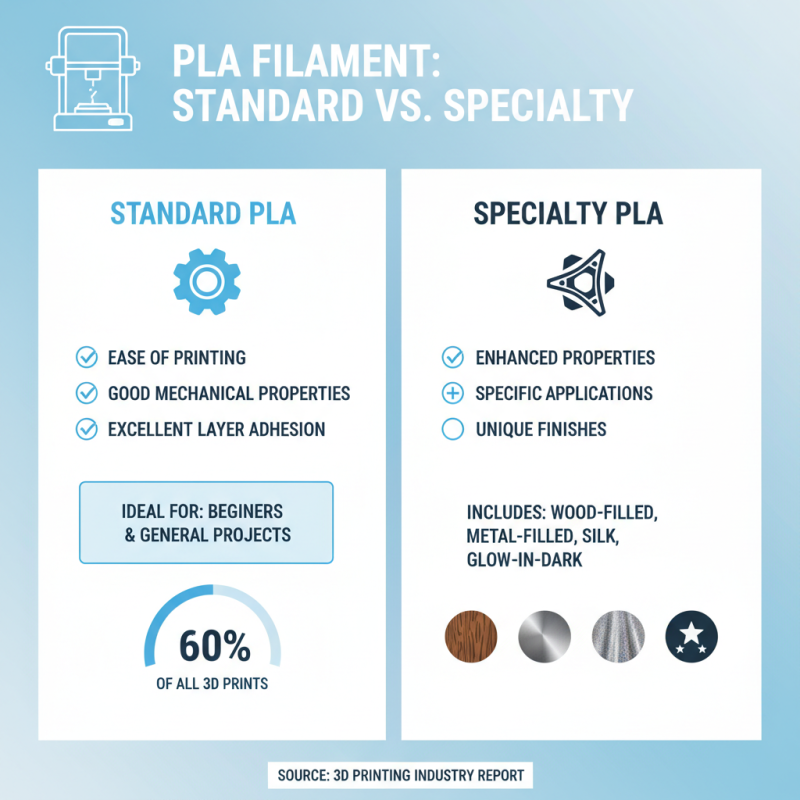

When selecting PLA filament for 3D printing, it's important to understand the differences between standard and specialty variants. Standard PLA is widely used due to its ease of printing and good mechanical properties, making it an ideal choice for beginners and general-purpose projects. According to a report by 3D Printing Industry, around 60% of all 3D printing applications use standard PLA. It provides excellent layer adhesion and minimal warping, allowing for smooth prints with reliable results.

On the other hand, specialty PLA filaments come in various formulations designed for specific applications. This category includes options like PLA with embedded materials, such as wood or metal powders, which mimic the appearance and feel of those substances while maintaining the advantages of PLA. Additionally, there are PLA variations that are engineered for enhanced strength or flexibility, making them suitable for functional prototypes or parts that demand higher performance. The demand for specialty PLA filaments has been steadily increasing, with the market expected to grow significantly, as reported by Grand View Research, driven by advancements in 3D printing technologies.

Tips for selecting the right filament include checking the compatibility with your 3D printer, as certain specialty PLAs may require specific settings for optimal results. Additionally, consider your project's requirements—whether you need aesthetic qualities, structural integrity, or flexibility, the right filament can make all the difference. Always read the technical data sheets to understand the properties and recommended print settings for the filament you choose.

When choosing the best PLA filament for your 3D printing projects, several key factors come into play. Firstly, the filament's diameter is crucial, as it directly impacts the compatibility with your 3D printer's nozzle. The most common diameters are 1.75mm and 2.85mm, with many printers designed to accept one of these sizes specifically. It's essential to select a filament that matches these specifications for optimal printing performance.

Another important consideration is the color and finish of the filament, which can significantly affect the aesthetic of the final product. PLA filament is available in a wide range of colors, including transparent, glossy, metallic, and matte finishes. This variety allows for creative flexibility depending on the project's requirements. Additionally, look for properties such as printability and layer adhesion, as high-quality filaments generally result in better layer bonding and fewer printing issues. Understanding these factors can help ensure a successful 3D printing experience with PLA filament.

When selecting PLA filament for your 3D printing projects, the quality of the filament is paramount. The filament industry has evolved significantly, with research suggesting that approximately 70% of printing issues stem from poor filament quality. A report from the 3D Printing Industry indicates that the physical properties of PLA, such as tensile strength, thermal stability, and ease of use, are critical factors to consider when choosing a supplier. High-quality PLA should exhibit consistent diameter, low warping tendencies, and minimal stringing, which can significantly improve print quality and reduce material waste.

Several reputable sources have emerged as leaders in providing quality PLA filament. Reports from industry experts highlight that several manufacturers prioritize rigorous quality control processes, ensuring that their products meet stringent performance standards. Look for suppliers that offer detailed specifications and test results, as well as feedback from the 3D printing community. According to a recent market analysis, brands that utilize eco-friendly practices in their production processes are seeing a 40% increase in consumer preference, making sustainability an important factor for many makers. By sourcing PLA filament from trusted suppliers, hobbyists and professionals alike can achieve superior results in their 3D printing endeavors.

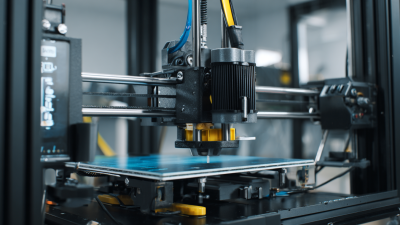

When working with PLA filament for your 3D printing projects, achieving optimal results relies heavily on understanding the nuances of the material and the printing process. One critical factor is temperature settings. Most experts recommend a nozzle temperature between 190°C to 220°C. According to a recent industry report, over 85% of filament manufacturers indicated that maintaining this range significantly reduces issues like stringing and warping, leading to cleaner prints with better detail retention.

Another vital tip is to adjust the print speed. Research shows that a speed of around 50 to 60 mm/s strikes a balance between print quality and time efficiency. Printing too fast can lead to under-extrusion, while printing too slowly may result in excessive filament heating and deformation. Additionally, ensuring the correct layer height is crucial; a standard range is between 0.1 mm and 0.2 mm, which allows for fine details while maintaining a solid structure. Using the right settings tailored to the specific type of PLA can dramatically enhance the finish and durability of your prints.