As the demand for 3D printing technology grows, so does the variety of materials available. One standout option is Water Washable 3D Printer Resin. Industry expert Dr. Alex Turner emphasizes its benefits, stating, “This resin simplifies the post-processing stage significantly.” This feature appeals to both hobbyists and professionals alike.

Water Washable 3D Printer Resin offers an eco-friendlier alternative to traditional resins. Users appreciate how it reduces the reliance on harsh chemicals. Yet, it's essential to understand that not all resins deliver equal performance. Some prints may lack the fine details that more conventional materials offer.

This innovation brings convenience but also challenges. Users must adequately balance print quality against ease of use. There is a learning curve with different brands, as results can vary widely. Adapting to these nuances ensures better project outcomes in the long run.

Water washable 3D printer resin is gaining popularity for various prototyping projects. One significant advantage is its ease of cleanup. Traditional resins often require harsh chemicals for washing. In contrast, water washable resin can be cleaned with plain water, making the process simpler and safer. This feature is especially beneficial in environments with limited ventilation.

In addition to ease of cleaning, water washable resin is generally less toxic than standard resins. Users can work with it without the need for heavy protective gear. This encourages more creators to explore 3D printing. The lower toxicity means fewer concerns about exposure during lengthy prototyping sessions.

**Tip:** Always wash your prints promptly. Waiting too long can cause the resin to cure and bond strongly to the print.

Another important aspect to consider is the variety of finishes obtainable with water washable resin. While some may not achieve as high a resolution compared to other materials, many find the results satisfactory. Be mindful that texture and detail can vary. Experimenting can yield surprising outcomes and might enhance your project.

**Tip:** Try layering different colors to see unique effects. You may stumble upon a design technique that becomes your signature style.

Water washable 3D printer resins are gaining popularity for many reasons. One significant benefit is their chemical safety. Traditional resins often contain harsh solvents that can be harmful during the printing process. Water washable resins, on the other hand, use water as a cleaning agent. This greatly reduces exposure to toxic chemicals. They present a safer option for hobbyists and professionals alike.

The environmental impact of these resins deserves attention. Many traditional resins require special disposal methods. Improper handling can lead to pollution. In contrast, water washable resins are generally easier to clean up. They reduce waste and lower the risk of environmental damage. However, some still express concern about additives. Not all resins are created equal. Users must research and select responsibly produced options. This ensures safer materials for both users and the environment.

Choosing water washable resins can seem straightforward. Yet, it raises questions about material sourcing and manufacturing practices. Not every option is eco-friendly. Awareness and knowledge are key in making informed choices. Transitioning to safer materials can be a positive step. However, it requires careful consideration of all factors involved.

When it comes to 3D printing, choosing the right resin can make a significant difference.

Water washable resins offer a cleaner and simpler alternative to traditional options.

They require less toxic solvents for cleaning, which is a huge advantage for hobbyists and professionals alike.

The ease of washing makes post-processing less cumbersome.

Traditional resin printing often involves several hazardous materials.

After printing, rinsing with alcohol can create fumes and mess.

In contrast, water washable resins need just plain water for the cleanup.

This can be especially beneficial for those new to 3D printing or working in small spaces.

Tip: Always wear gloves when handling resins, even water washable ones.

It's better to be safe, as direct contact can still cause issues.

The adaptability of water washable resins is impressive. They don’t always achieve the same surface finish as traditional options, so quality can vary.

Testing a small batch can be wise before committing fully. Each project may require a different approach.

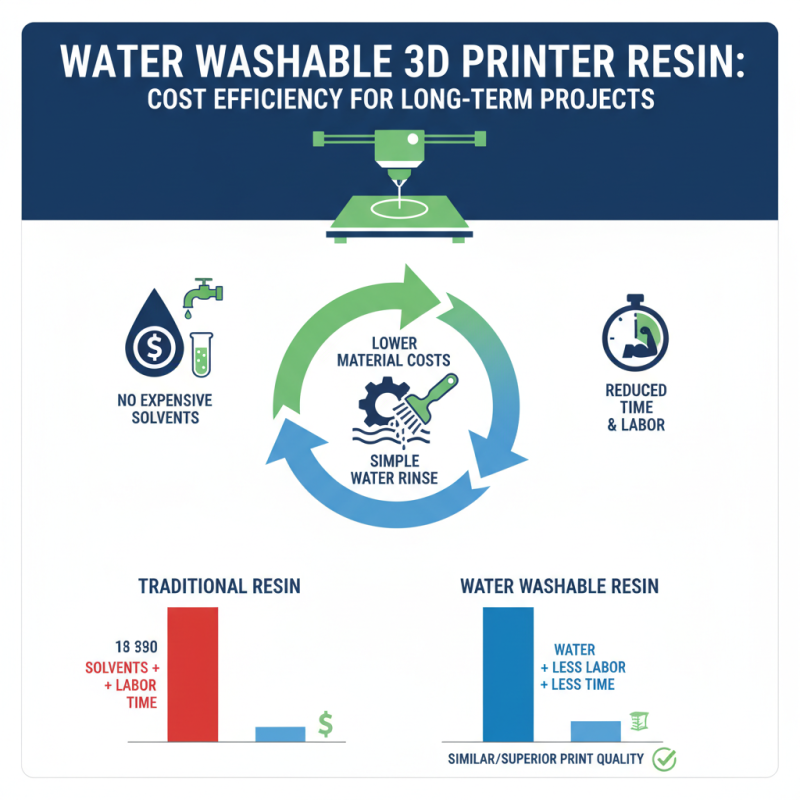

Water washable 3D printer resin offers significant cost efficiency for long-term projects. Unlike traditional resins, these materials eliminate the need for expensive solvents. Users can simply wash their prints with water. This process cuts down both time and labor costs. Additionally, water washable resins often provide similar or even superior print quality.

When planning a project, consider the overall expenses. While the initial cost of water washable resins might seem higher, their lasting benefits are worth it. They simplify cleanup, which can be a time sink. However, some users find the washing process can leave residue. It requires careful attention and sometimes multiple washes to achieve a perfect finish. This aspect can be a learning curve for beginners.

Moreover, waste reduction is a crucial advantage. These resins generate less toxic waste compared to their counterparts. This is essential for those who value sustainability. Yet, not every user may grasp the importance of proper disposal methods. Without it, the environmental benefits diminish. While water washable resin holds promise, it invites users to improve their practices and processes.

Cleaning and post-processing can often be a hassle in 3D printing. Traditional resins usually require harsh chemicals for cleaning. This can be daunting for new users. Water wash compatible resins present a user-friendly alternative. They dissolve in water, making cleanup simple and safe. Just rinse your prints under running water. It’s a straightforward process that saves time and effort.

User experiences with water-soluble resins highlight their practical advantages. For instance, users report swift cleanup times. However, getting the wash time right can be tricky. Some users find prints still sticky after rinsing. In these cases, patience is essential. Allowing the prints to dry thoroughly improves the finish. This is a common learning curve, but it leads to better results. The ease of cleaning encourages more experimentation, fostering creativity.

Post-processing with water soluble resins is generally smoother. Users can apply paints or finishes without extensive prep work. Some report minor adhesion issues with specific paints. These small setbacks can serve as lessons in the learning process. Understanding how different materials react is vital. This exploration can transform a simple project into something impressive. It’s all about refining techniques and embracing imperfections along the way.