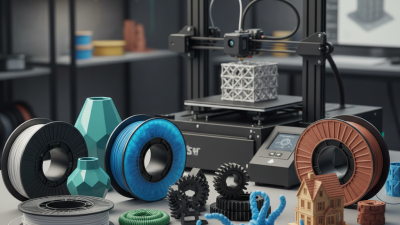

In recent years, the 3D printing industry has witnessed a remarkable transformation, driven largely by the evolution of 3D printer filaments. As a key component in this technology, these materials not only influence the printing process but also determine the quality and durability of the final product. According to a report by the 3D Printing Industry Research, the global market for 3D printer filaments is projected to reach $5.1 billion by 2027, driven by innovations in filament compositions and applications across various sectors.

Experts in the field, such as Dr. Emily Chen, a leading researcher in additive manufacturing, emphasize the significance of selecting the right filament for specific projects. Dr. Chen states, "The choice of 3D printer filaments can dramatically affect not just the structural integrity of printed objects, but also their performance in real-world applications." With a plethora of options available, ranging from standard PLA to high-performance nylon composites, understanding the characteristics and use cases of different filaments is crucial for both hobbyists and professionals alike.

As we delve into the best 10 types of 3D printer filaments you need to know about, it becomes evident that making informed choices can enhance the efficiency and effectiveness of 3D printing endeavors, ultimately paving the way for innovation across industries.

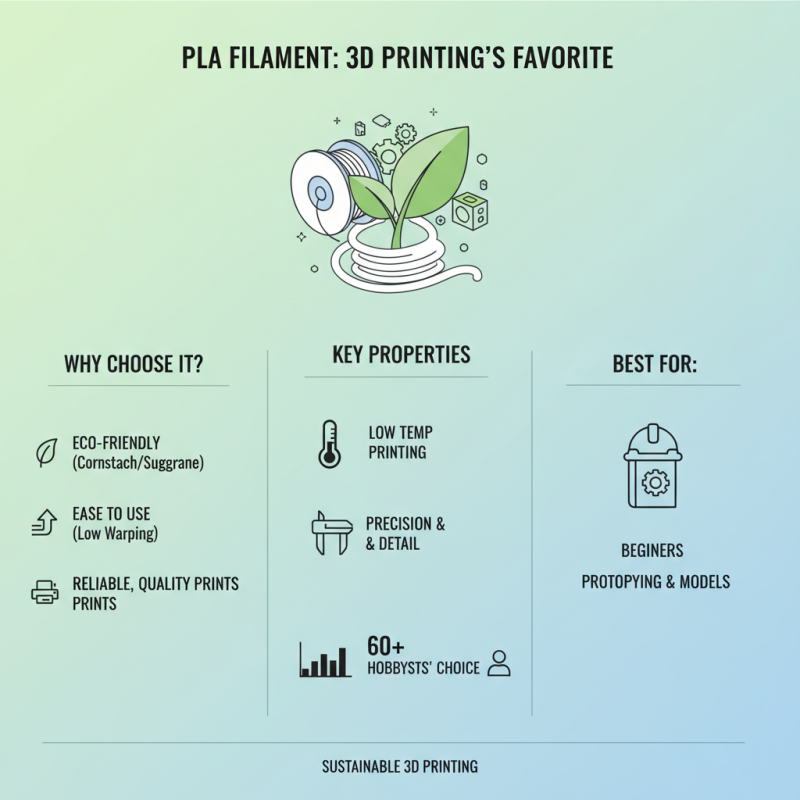

In the world of 3D printing, the choice of filament significantly impacts the quality and functionality of the printed objects. There are several types of filaments, each with unique properties suited for various applications. A comprehensive report from the 3D Printing Industry reveals that PLA (Polylactic Acid) holds a significant market share, accounting for nearly 45% of the global filament usage in 2022. PLA is favored for its ease of use and biodegradable properties, making it an excellent choice for beginners and environmentally-conscious makers.

In contrast, ABS (Acrylonitrile Butadiene Styrene) is another popular filament, known for its durability and heat resistance. This material is often employed in industrial applications, as outlined in the 2023 Global 3D Printing Report, with ABS usage projected to grow by 12% annually in the consumer segment. Moreover, specialized filaments like PETG (Polyethylene Terephthalate Glycol) and TPU (Thermoplastic Polyurethane) are gaining traction due to their flexibility and strength, broadening the scope of potential applications from consumer goods to medical devices. The diverse range of materials available today allows for innovative and functional designs that cater to both hobbyists and professionals alike.

PLA (Polylactic Acid) filament is one of the most popular materials used in 3D printing, particularly favored for its ease of use and environmentally friendly properties. Derived from renewable resources like cornstarch or sugarcane, PLA is biodegradable, making it a suitable option for sustainable manufacturing. According to a report by the 3D Printing Industry, over 60% of hobbyist printers prefer PLA for its reliability and the quality of prints it produces. Its low thermal expansion and minimal warping characteristics allow for precise printing at lower temperatures, making it an excellent choice for beginners and professional users alike.

When utilizing PLA filament, it's essential to consider its limitations, especially in high-temperature environments. PLA has a glass transition temperature of around 60°C, which means it can deform if exposed to heat. For optimal printing, setting the nozzle temperature between 190°C to 220°C is recommended, as it ensures good layer adhesion while minimizing the risk of clogging.

Tips: For smooth and high-quality prints, always ensure your print bed is properly leveled. A well-leveled bed can significantly reduce print failures and enhance the overall finish of your project. Additionally, avoid storing PLA in areas with high humidity to prevent moisture absorption, which can affect the filament's performance during printing.

ABS filament, short for Acrylonitrile Butadiene Styrene, is renowned for its strength and durability, making it a popular choice in the world of 3D printing. Its unique blend of rigidity and toughness gives it an edge over other materials, particularly in applications requiring robust and long-lasting parts. According to a report from ResearchAndMarkets, the global 3D printing materials market, which includes filaments like ABS, is projected to grow significantly, driven by increasing demand across various industries such as automotive, aerospace, and consumer goods.

One of the key benefits of ABS filament is its ability to withstand high temperatures and impact without compromising its structural integrity. This resilience makes it particularly suitable for functional prototyping and end-use parts. A study by Wohlers Associates indicates that the demand for durable 3D printed parts is rising, with ABS being a material of choice for applications that require both strength and lightweight characteristics. Moreover, the versatility of ABS allows it to be easily post-processed, enabling users to sand, paint, or apply other finishes for enhanced aesthetics and functionality in their projects, further solidifying its position in the market.

PETG filament has gained significant traction in the 3D printing community due to its unique properties that cater to both beginners and experienced users. Combining the best qualities of other materials, PETG is known for its toughness and flexibility, making it an ideal choice for a variety of applications, from functional prototypes to aesthetic models. According to industry reports, PETG offers excellent layer adhesion, allowing for stronger prints compared to PLA while also being easier to print than ABS. Its chemical resistance and durability make it suitable for end-use parts in sectors like automotive and product design.

When using PETG, it's essential to keep a few tips in mind to ensure optimal print quality. First, maintain a consistent printing temperature between 230°C and 250°C, as minor fluctuations can lead to stringing or oozing. Additionally, using a heated bed can help improve adhesion and prevent warping, which is crucial for successful printing, especially in larger models. Lastly, consider adjusting your print speed; while faster speeds are possible, a moderate pace of around 40-60 mm/s can yield higher quality results.

Experimenting with different print settings and configurations can help you unlock the full potential of PETG. Its versatility in combining rigidity with some degree of flexibility opens up new possibilities for creative designs. As 3D printing technology continues to evolve, understanding materials like PETG will empower enthusiasts and professionals alike to push the boundaries of innovation.

| Filament Type | Toughness | Flexibility | Printing Temperature (°C) | Applications |

|---|---|---|---|---|

| PLA | Medium | Low | 180-220 | Prototyping, Toys |

| ABS | High | Medium | 210-250 | Enclosures, Functional Parts |

| PETG | High | Medium | 220-250 | Mechanical Parts, Bottles |

| TPU | Medium | High | 210-230 | Flexible Parts, Seals |

| Nylon | Very High | Medium | 240-260 | Strong Parts, Functional Prototypes |

| ASA | High | Medium | 240-260 | Outdoor Applications |

| HIPS | Medium | Low | 230-250 | Support Material |

| PVA | Low | Medium | 180-220 | Water-Soluble Support |

| Metal-infused | High | Medium | 200-250 | Aesthetic Parts, Jewelry |

| Wood-infused | Medium | Low | 190-220 | Decorative Items |

When it comes to 3D printing, specialty filaments like Nylon and TPU (Thermoplastic Polyurethane) are gaining significant traction due to their unique properties and wide-ranging applications. According to a recent report by Smithers Pira, the demand for flexible and durable materials in the 3D printing sector is expected to grow at a CAGR of 23% between 2020 and 2025. This rapid growth showcases the increasing interest in filaments like TPU, which offers exceptional elasticity and wear resistance, making it suitable for producing items like gaskets, seals, and even footwear components.

Nylon, another standout in the specialty filament category, is prized for its strength and versatility. It is known to absorb moisture, which can enhance its mechanical properties when printed correctly. Market research indicates that Nylon filaments are becoming increasingly popular among industries that require high-performance parts, such as automotive and aerospace. The advantages of Nylon include its ability to withstand high temperatures and chemical exposure, which can be critical for functional prototypes and end-use applications. As the 3D printing landscape evolves, utilizing these specialty filaments will empower designers and engineers to push the boundaries of what is possible in additive manufacturing.