High Wax Resin for 3D Printers has transformed the industry, offering precision and detail that many users crave. According to Mark Thompson, a leading expert in 3D printing, "Choosing the right resin is crucial for achieving optimal results." This emphasizes the growing importance of resin selection among enthusiasts and professionals alike.

Many users may overlook the nuances of different wax resins. Each resin type varies in quality and usage. High Wax Resin for 3D Printers stands out for its unique properties, enabling sharper details and smoother finishes. Yet, it's not always easy to navigate through the options available. Beginners might feel overwhelmed by the choices.

Ultimately, the perfect match may differ based on specific projects and needs. Users should consider their own experience and preferences when choosing. An informed decision can greatly enhance the final outcome of prints. The world of High Wax Resin for 3D Printers is vast, yet filled with potential for those who dare to explore it.

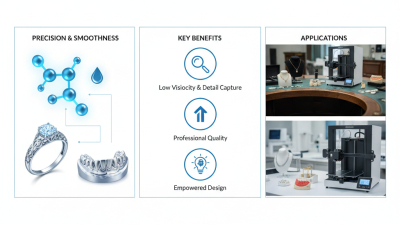

When considering high wax resins for 3D printing, you encounter a range of choices. High wax resins are ideal for creating detailed models with smooth finishes. They are especially popular for the jewelry and dental industries. Many options offer excellent casting properties. This ensures clean and precise results in the final product.

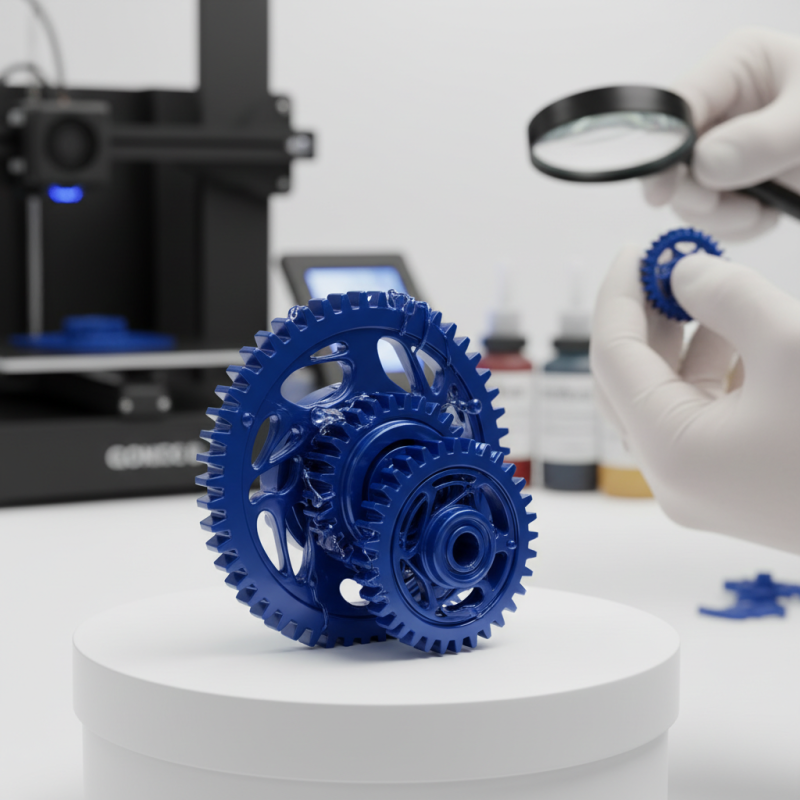

One option might yield intricate patterns. However, it may not provide the best durability. Another has impressive flow characteristics, yet can produce slight surface imperfections. Finding the balance between detail and strength can be tricky. Some users report difficulties in achieving optimal settings on different machines. This could affect the final quality of their prints.

Experimenting with different resins may lead to surprising outcomes. For example, even a small change in temperature can alter the print's characteristics. Users often reflect on their preferences, noting that not all resins perform as expected. The journey to discover the best fit for your projects takes time and persistence. Each resin has its quirks, and learning from those experiences is key.

High wax resin presents unique benefits in 3D printing. It offers exceptional detail and smooth finishes.

This is critical for creating intricate designs. The higher wax content allows for easier burnout in casting processes.

Models printed with high wax resin show fine details that can impress any viewer.

Tips: Always check the compatibility of your printer.

High wax resin can vary significantly. Make sure you adjust the printing settings accordingly.

Experimentation is key. Not every printer handles all resins equally.

In addition, consider environmental factors. High temperatures can affect resin performance.

It's crucial to store the resin in a cool place. This simple step can help maintain print quality.

Remember, high wax resin might not be perfect for every project. Some prints may require adjustments before achieving desired results.

A little patience can go a long way in the creation process.

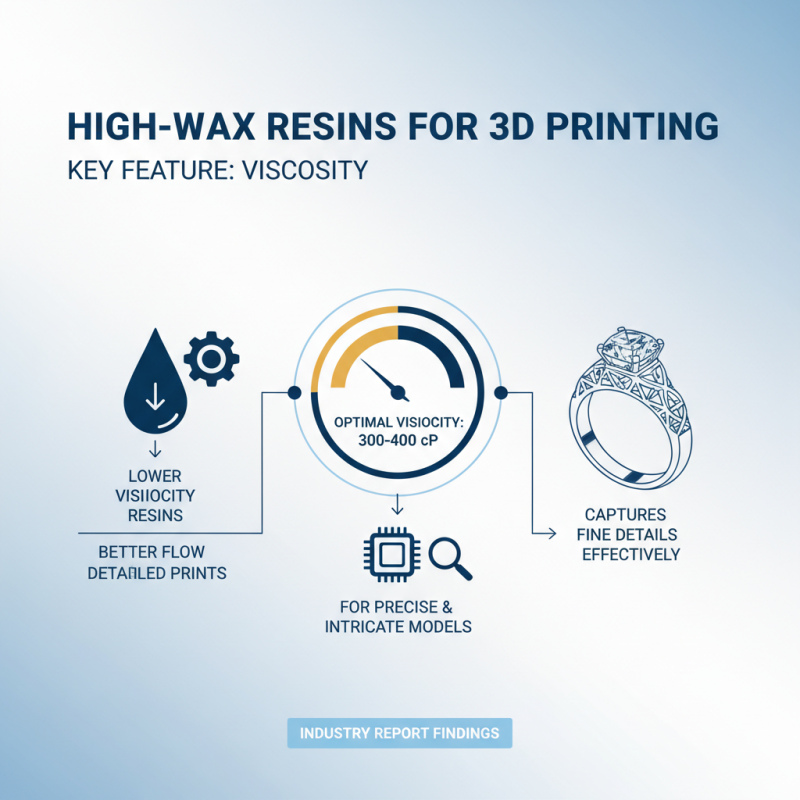

When selecting high wax resins for 3D printing, it’s crucial to consider specific key features. One primary characteristic is viscosity. Lower viscosity resins flow better, ensuring detailed prints. According to a recent industry report, optimal viscosity for high wax resins should be around 300-400 cP for precise models. This helps in capturing intricate details effectively.

Another feature to keep in mind is the melting point. Resins with lower melting points allow for easier post-processing. Ideally, a melting point below 70°C is best for usability. This feature can significantly enhance your production efficiency.

**Tip**: Always run a few test prints before committing fully.

Durability is also vital. High wax resins should offer adequate hardness for structural integrity. While softness can aid in intricate designs, it can compromise durability if not balanced correctly. A well-structured resin should fall in the range of 80-90 Shore D hardness.

**Tip**: Analyze different compositions. Resins may behave differently under varying conditions.

Considerations like shrinkage rates are essential. Excessive shrinkage can lead to dimensionally inaccurate prints. Research indicates that a shrinkage rate of less than 1% is ideal for professional applications. This can save time and resources in the long run.

When searching for the right high wax resin for your 3D printer, it’s essential to compare the leading options on the market. High wax resins are known for their excellent casting properties and detail fidelity. However, not all resins perform equally, and subtle differences can impact your work.

Some resins offer a smooth finish, while others may leave a rough texture. It's crucial to evaluate your project needs. Do you prioritize speed or detail? Some resins cure faster but might compromise on the resolution. Consider factors like viscosity and how well the resin picks up minute details during printing.

Tips: Always conduct a test print. This step helps to identify any shortcomings in the resin's performance. Adjust your printer settings as needed. Be prepared for a bit of trial and error. Finding the perfect resin can be a journey rather than a quick fix.

Test the flexibility of your chosen resin. Some high wax resins are more brittle, which could lead to issues if your model has intricate parts. Always handle prints carefully to avoid damage. Assessing the longevity of the resin is also vital. Over time, some materials may degrade, affecting the quality of your prints.

When choosing high wax resins for 3D printers, user feedback plays a crucial role. Many users emphasize the importance of smooth finishes. They often mention how the resin helps capture fine details. This feature is especially important for intricate designs. However, some users report occasional issues with brittleness. This feedback highlights the need for careful handling.

Durability is another major point of discussion. Some users love how high wax resins hold up during printing. Others, however, face challenges during post-processing. They have noted that certain resins can stick to supports more than expected. This can lead to frustrating failures. Users recommend using the right tools for removal.

Overall, reviews indicate a mixed experience. While many praise the detailed results, they also highlight room for improvement. Users suggest greater clarity on usage instructions. This would assist both beginners and seasoned users. Finding the right balance in performance and usability is important.

| Resin Type | Viscosity (cP) | Cure Time (seconds) | User Rating (out of 5) | Applications |

|---|---|---|---|---|

| High Wax Resin A | 350 | 45 | 4.7 | Jewelry & Dental |

| High Wax Resin B | 400 | 50 | 4.5 | Prototype & Casting |

| High Wax Resin C | 300 | 40 | 4.8 | Medical Devices |

| High Wax Resin D | 450 | 60 | 4.6 | Industrial Parts |

| High Wax Resin E | 325 | 30 | 4.9 | Art & Design |